Alumina ceramics, a pivotal member of the advanced ceramic materials family, have become an indispensable solution for demanding industrial conditions due to their exceptional comprehensive properties. From high-wear mining chutes to high-purity semiconductor equipment, this material, primarily composed of aluminum oxide (آل₂O₃), is redefining the boundaries of engineering design. This article serves as an in-depth guide for industry engineers, procurement specialists, and technical decision-makers, systematically analyzing the core advantages and key applications of alumina ceramics, and providing professional selection advice to help your enterprise make more informed material decisions.

Quick Navigation

What are Alumina Ceramics?

Alumina ceramic is a structural ceramic material with α-Al₂O₃ as its main crystalline phase, with Al₂O₃ content typically ranging from 75% ل 99.9%. Based on purity, it can be classified into various grades, such as the common 92%, 95%, و 99% alumina. Higher purity generally leads to superior key properties such as hardness, wear resistance, corrosion resistance, and temperature resistance. Through precise control of raw material ratios and sintering processes, precision components can be manufactured to meet the needs of diverse industrial applications.

Core Performance Advantages of Alumina Ceramics

Alumina ceramics stand out among many industrial materials due to their outstanding performance across several critical dimensions.

Unparalleled Hardness and Wear Resistance

Hardness measures a material’s ability to resist localized indentation by hard objects and forms the basis of its wear resistance. Alumina ceramics exhibit exceptional performance in this regard.

Its Mohs hardness reaches level 9, second only to diamond, enabling it to effectively resist the erosion and scratching of high-strength abrasive materials. In Rockwell hardness tests, its value can reach HRA80-90, far exceeding most metallic materials.

This high hardness endows alumina ceramics with excellent wear resistance. According to measurements by the Powder Metallurgy Research Institute of Central South University, its wear resistance is 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. This means that under similar wear conditions, using alumina ceramic components can significantly extend equipment service life, reduce downtime for maintenance, and thus substantially lower operating costs.

| Performance Indicator | سيراميك الألومينا | Manganese Steel | High-Chromium Cast Iron |

|---|---|---|---|

| Relative Wear Resistance | 266 | 1 | 1.55 |

| Mohs Hardness | 9 | 5-6 | 6-7 |

| Rockwell Hardness | HRA80-90 | HRC20-50 | HRC58-65 |

Excellent Corrosion Resistance and Chemical Stability

Beyond physical wear, chemical corrosion is another major cause of equipment failure. As an amphoteric oxide, alumina ceramics exhibit excellent chemical inertness in both acidic and alkaline environments. They effectively resist erosion from various strong acids, strong bases, and molten metals, making them an ideal choice for handling corrosive media in chemical, metallurgical, and other industries. Their chemical stability remains outstanding even at high temperatures, showing little reactivity with other substances.

Superior High-Temperature Performance and Thermal Stability

Alumina ceramics have a melting point of up to 2050℃, allowing them to maintain structural integrity and mechanical strength in extreme high-temperature environments. Their good thermal conductivity and low coefficient of thermal expansion also provide excellent thermal shock resistance, enabling them to withstand rapid temperature changes without cracking. This property makes them widely used in refractory materials, high-temperature furnace tubes, thermocouple protection tubes, and other fields.

Outstanding Electrical Insulation Properties

Alumina ceramics are typical high-performance electrical insulating materials, possessing extremely high volume resistivity and dielectric strength. Even at high temperatures, they maintain good insulation properties. بالتالي, they are extensively used in manufacturing substrates, packaging enclosures, high-voltage insulators, and various structural components requiring electrical isolation in electronic devices.

Key Application Areas: Alumina Wear-Resistant Ceramic Liners

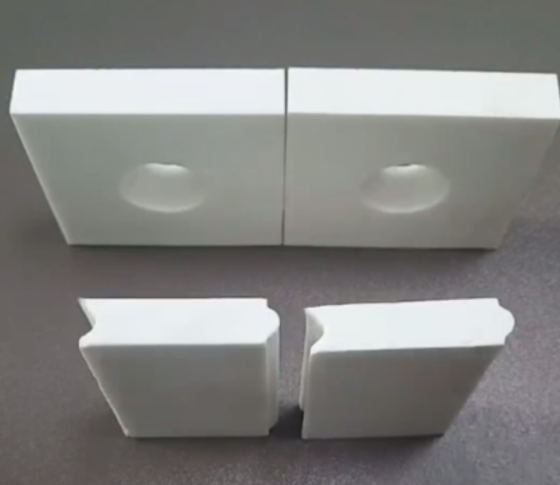

Wear-resistant ceramic liner with card slots

Among numerous applications, alumina wear-resistant ceramic liners are one of the most representative and widely used products. They are typically installed as tiles, plates, or pipe linings on the surfaces of equipment subjected to severe material abrasion, acting as robust “armor.”

Mining and Mineral Processing Industries

The processes of ore extraction, crushing, and transportation involve severe wear. Applying alumina wear-resistant ceramic liners to ball mill linings, ore chutes, hoppers, and conveying pipeline elbows can effectively resist the impact and abrasion of ore, extending equipment life by several to dozens of times.

Thermal Power and Cement Industries

In coal conveying and ash removal systems of thermal power plants, and in raw and clinker material conveying equipment of cement plants, high-speed moving powdery materials cause rapid wear to pipes and equipment. Using ceramic-lined pipes (especially elbows) and cyclone separators has become a standard industry solution, effectively addressing wear-induced leaks and downtime.

Steel and Metallurgy Industries

Various chutes, hoppers, and mixers in the sintering, coking, and ironmaking systems of steel mills are constantly subjected to friction from hard materials like iron ore and coke. Installing alumina wear-resistant ceramic liners not only significantly enhances durability but also, with their smooth surface, reduces material blockage and improves production efficiency.

Wear-resistant ceramic lining

How to Select the Right Alumina Ceramics for Your Application?

Facing alumina ceramic products of varying purities and specifications, making the correct choice is crucial to ensuring optimal performance. Here are selection recommendations from an engineering application perspective.

Step One: Determine Purity Grade Based on Working Conditions

Purity is a core factor determining the performance and cost of alumina ceramics.

- 99% and above (High-Purity Type): Suitable for extremely harsh conditions, such as ultra-high temperature environments, strong corrosive media, or semiconductor and medical fields with extremely high demands for material purity. It has the highest cost but also the strongest performance.

- 95%-96%: This is the most widely used and cost-effective grade. It achieves a good balance between hardness, wear resistance, and mechanical strength, sufficient for most industrial wear scenarios, such as mining, cement, and ports.

- 85%-92%: Suitable for applications with relatively lighter wear and higher cost sensitivity. Although its performance is not as good as high-purity products, it can still provide protection far exceeding metal materials in many medium-to-low load conditions.

Step Two: Focus on Key Technical Parameters

In addition to purity, the following core technical indicators should be considered during procurement:

- كثافة (g/cm³): Higher density usually means better ceramic compactness and fewer internal pores, leading to higher hardness and strength. High-quality 95% alumina ceramics should have a density of no less than 3.65 g/cm³.

- صلابة (HRA): Directly reflects its ability to resist wear. A Rockwell hardness of HRA85 or above is the threshold for high-quality wear-resistant ceramics.

- Flexural Strength (MPa): Measures the material’s ability to resist bending without breaking. This is an important indicator for structural components that need to withstand certain mechanical stresses.

- Fracture Toughness (MPa·m¹/²): Reflects the material’s ability to resist crack propagation. Although ceramic materials are generally brittle, higher fracture toughness means better impact resistance and reliability.

Step Three: Consider Installation and Structural Design

Even the best materials can be rendered ineffective by improper installation. When selecting alumina wear-resistant ceramic liners, consider:

- Bonding Solution: Ensure the use of high-strength ceramic adhesives compatible with the working temperature and environment.

- Liner Design: For high-impact conditions, choose liners with dovetail grooves or interlocking structures, combined with welding or other methods, to form a dual mechanical + adhesive fixation, effectively preventing detachment.

- Dimensional Tolerance: Precise dimensional tolerances ensure tight joints between liners, reducing gaps and preventing material from “hollowing out” the substrate from the gaps.

Common Industry Issues and Summary

In long-term applications, users may encounter some challenges. For example, why do ceramic liners detach or crack? This is usually related to adhesive failure, improper substrate surface treatment, or significant impact forces. Choosing reliable suppliers and professional construction teams, and adopting more advanced fixing technologies such as dovetail interlocking, are key to solving these problems.

In summary, alumina ceramics, with their comprehensive advantages in hardness, wear resistance, corrosion resistance, and high-temperature performance, provide an efficient, reliable, and cost-effective material solution for modern industry. From a basic understanding of performance to targeted application analysis, and then to professional selection considerations, a deep grasp of the characteristics of this advanced material will help your enterprise gain stronger equipment reliability and lower operating costs in fierce market competition.

جيفينج سيراميك

جيفينج سيراميك