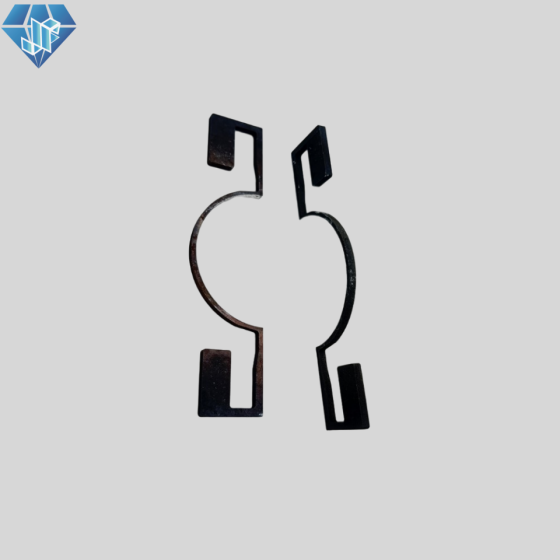

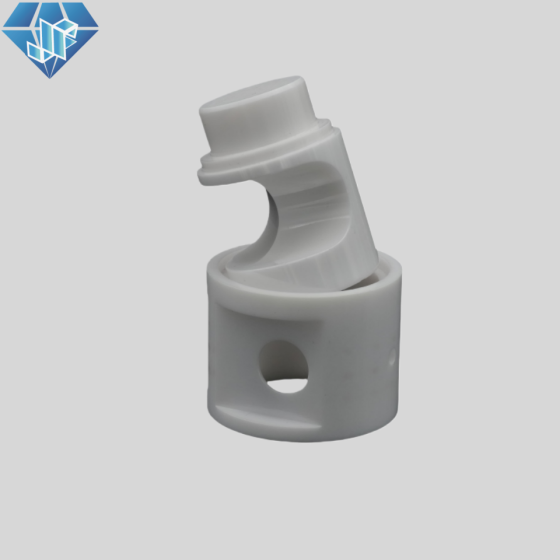

The Ultimate Solution for High-Temperature Industrial Applications

JiFeng Ceramics manufactures high-precision كربيد السيليكون (كربيد كربيد) ceramic shims and spacers designed for critical industrial applications where conventional metal or lower-grade ceramic components fail. Our SiC components, available in Sintered Silicon Carbide (SSiC) and Reaction Bonded (RBSiC) grades, deliver unmatched performance in extreme environments.

Key Product Specifications:

|

Feature

|

Specification

|

Benefit

|

|

مادة

|

Sintered SiC (SSiC) / Reaction Bonded SiC (RBSiC)

|

Optimized for specific application needs (purity vs. cost).

|

|

Precision

|

Thickness Tolerances down to ±0.005mm

|

Ensures exact alignment and minimal thermal expansion mismatch.

|

|

Surface Finish

|

Lapped and Polished to رع < 0.1ميكرومتر

|

Reduces friction and wear in dynamic sealing or sliding applications.

|

|

استقرار

|

High Young’s Modulus (Zero Deformation)

|

Maintains structural integrity under heavy mechanical and thermal loads.

|

|

Customization

|

Build-to-Print Services

|

Rapid prototyping and manufacturing based on your CAD drawings.

|

SiC Ceramic Shims: Outperforming Traditional Materials

Silicon Carbide is one of the hardest and most chemically resistant advanced ceramics available. Its unique covalent bonding structure grants it superior properties compared to common industrial materials like Stainless Steel or Alumina (آل₂O₃).

|

Property

|

Sintered SiC (SSiC)

|

الألومينا (99.5% آل₂O₃)

|

Stainless Steel (316L)

|

|

Max Service Temp

|

~1700°C

|

~1650°C

|

~870°C

|

|

صلابة (Vickers)

|

>2500 الجهد العالي

|

~1500 HV

|

~200 HV

|

|

الموصلية الحرارية

|

~120 W/m·K

|

~30 W/m·K

|

~15 W/m·K

|

|

Corrosion Resistance

|

Excellent (Acids/Alkalis)

|

جيد (Acids)

|

Poor (Strong Acids/Chlorides)

|

|

Wear Resistance

|

Exceptional

|

جيد

|

Poor

|

جيفينج سيراميك

جيفينج سيراميك