Aperçu des céramiques de zircone

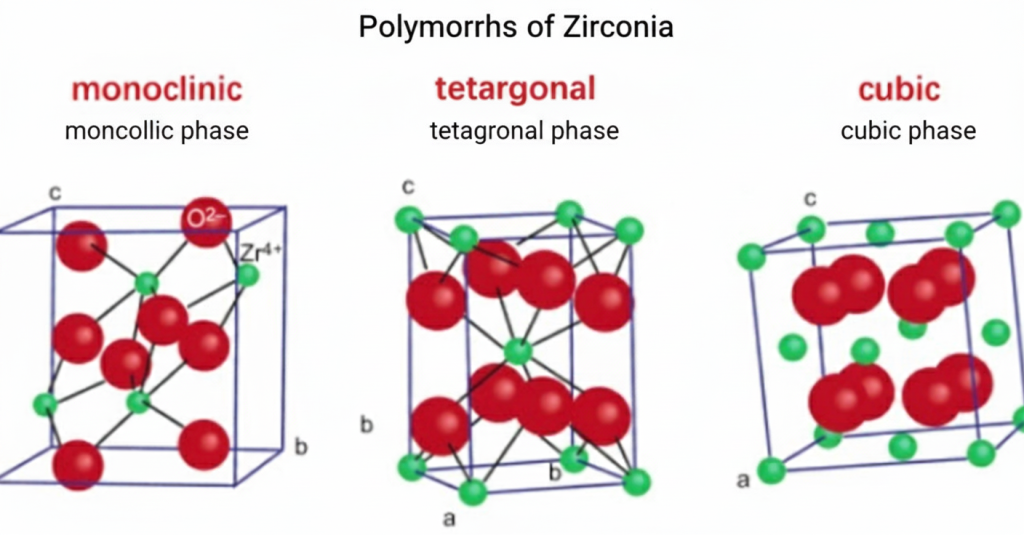

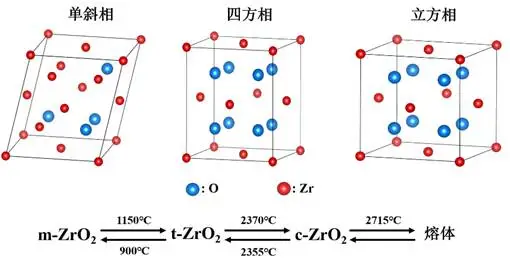

La zircone est un oxyde cristallin blanc composé de zirconium (Zr) et de l'oxygène (Ô), de formule chimique ZrO₂. La zircone pure existe en trois phases cristallines à différentes températures: monoclinique (m-ZrO₂), tétragonal (t-ZrO₂), et cubique (c-ZrO₂). La transformation de la phase tétragonale à la phase monoclinique s'accompagne d'une expansion volumique d'environ 3-5%, ce qui peut entraîner des fissures dans la céramique lors du refroidissement. Pour surmonter ce problème, stabilisateurs (tel que l'oxyde d'yttrium Y₂O₃, oxyde de magnésium MgO, oxyde de calcium CaO, etc.) sont généralement ajoutés pour stabiliser les phases cristallines à haute température, réalisant ainsi un “trempe par transformation de phase” mécanisme et améliorant considérablement la ténacité à la rupture du matériau.

Zircone (ZrO₂) céramique, en raison de leurs excellentes propriétés mécaniques et de leurs caractéristiques physico-chimiques uniques, occupent une position cruciale dans le domaine des céramiques avancées. Connu sous le nom “en céramique en acier,” il est largement utilisé dans les domaines de haute technologie tels que l'aérospatiale, biomédecine, électronique et communications, et machines de précision, ce qui en fait l'un des matériaux clés indispensables dans l'industrie moderne.

Formes cristallines d'oxyde d'aluminium

Oxyde d'aluminium (Al₂O₃) est connu pour exister dans plus de dix structures cristallines, y compris α, c, b, ou, d, je, h, κ-Al₂O₃ et une phase amorphe. Parmi ceux-ci, les plus courants et les plus importants sont α-Al₂O₃, γ-Al₂O₃, et β-Al₂O₃. Ces différentes formes d'oxyde d'aluminium présentent des différences significatives en termes de structure et de propriétés, qui déterminent leurs domaines d’application respectifs.

- Structure cristalline: Appartient au groupe spatial P2₁/c, présentant une symétrie de structure cristalline relativement faible et un arrangement atomique relativement lâche. La cellule unitaire a une symétrie monoclinique.

- Conditions de stabilité: À température et pression normales, le dioxyde de zirconium existe en phase monoclinique, qui est la phase stable du dioxyde de zirconium à température ambiante.

- Propriétés physiques: La densité est d'environ 5.65-5.68 g/cm³, et il a une dureté relativement faible. La structure cristalline est sujette à la déformation sous contrainte.

- Structure cristalline: Il appartient au groupe spatial P4₂/nmc, avec une cellule unitaire tétragonale et un arrangement atomique plus régulier et ordonné, présentant une symétrie cristalline élevée.

- Conditions de stabilité: Lorsque la température atteint environ 1150 ℃, la zircone monoclinique subit une transition de phase, se transformant en phase tétragonale. La phase tétragonale est stable dans la plage de température de 1 150 ℃ à 2 370 ℃..

- Propriétés physiques: La densité est d'environ 6.10 g/cm³, et la dureté et la résistance sont améliorées par rapport à la phase monoclinique. La structure cristalline présente une bonne stabilité à haute température.

- Structure cristalline: Il appartient au groupe spatial Fm3m, avec une cellule unitaire cubique parfaite et un arrangement hautement symétrique d'atomes, ce qui en fait la phase la plus symétrique parmi les structures cristallines de dioxyde de zirconium.

- Conditions de stabilité: Quand la température monte à 2370℃, la phase tétragonale du dioxyde de zirconium se transforme ensuite en phase cubique. La phase cubique est stable dans la plage de température de 2370℃-2715℃ (point de fusion).

- Propriétés physiques: Il a une densité d'environ 6.27 g/cm³, possède une dureté élevée, force, et stabilité thermique, et sa structure cristalline présente d'excellentes performances à haute température.

Ces trois formes cristallines de zircone se transforment les unes dans les autres sous différentes températures et environnements chimiques., et leurs propriétés et applications varient en fonction de la structure cristalline. En contrôlant la température, ajout de stabilisateurs, et d'autres méthodes, la structure cristalline de la zircone peut être ajustée pour répondre aux besoins d'application de différents domaines.

Performances et avantages de base

|

Propriété

|

Valeur typique

|

Unité

|

Remarques

|

|

Densité

|

5.85 – 6.05

|

g/cm³

|

Haute densité

|

|

Dureté Vickers

|

1200 – 1400

|

HT

|

Excellente résistance à l'usure

|

|

Résistance à la flexion

|

900 – 1200

|

MPa

|

Capacité de charge élevée

|

|

Résistance à la rupture

|

8 – 12

|

MPa·m^1/2

|

Caractéristique clé de “en céramique en acier”

|

|

Module élastique

|

200 – 220

|

GPa

|

Bonne rigidité

|

Au-delà des propriétés mécaniques, les céramiques de zircone présentent également une stabilité physico-chimique remarquable:

- Résistance aux hautes températures: Point de fusion jusqu'à 2715℃, fonctionnement stable dans des environnements à haute température.

- Résistance à la corrosion: Forte résistance aux milieux chimiques tels que les acides, alcalis, et des sels, adapté aux environnements chimiques difficiles.

- Faible conductivité thermique: Conductivité thermique aussi faible que 2-3 Avec(m·K), ce qui en fait un excellent isolant thermique.

- Coefficient de dilatation thermique: Environ 10.5 × 10⁻⁶/K, proche des matériaux métalliques (par ex., acier), facilitant la liaison composite avec les métaux.

- Biocompatibilité: Non toxique, non irritant, et bonne compatibilité avec les tissus humains, ce qui en fait un matériau biomédical idéal.

Tableau des propriétés de la céramique de zircone

|

Propriété |

Unité |

Z-100 |

Z-200 |

Z-300 |

ZM-100 |

ZB-100 |

|---|---|---|---|---|---|---|

|

Composition du matériau |

– |

ZrO₂-Y₂O₃ |

ZrO₂-Y₂O₃ |

ZrO₂-Y₂O₃ |

ZrO₂-Y₂O₃ |

ZrO₂-Y₂O₃ |

|

Couleur |

– |

Blanc |

Blanc |

Blanc |

Jaune |

Bleu |

|

Densité |

g/cm³ |

6.00 |

6.03 |

6.04 |

5.70 |

6.03 |

|

Résistance à la flexion |

MPa |

900 |

950 |

1100 |

450 |

1100 |

|

Résistance à la compression |

MPa |

2100 |

2200 |

2300 |

1600 |

2300 |

|

Module élastique |

GPa |

200 |

210 |

220 |

210 |

220 |

|

Résistance à la rupture |

MPa·m¹/² |

9.0 |

– |

9.0 |

5.5 |

7.0 |

|

Coefficient de Poisson |

– |

0.3 |

0.3 |

0.3 |

0.3 |

0.3 |

|

Dureté (HRA) |

HRA |

89 |

90 |

90 |

88 |

90 |

|

Dureté Vickers |

HV1 |

1250 |

1450 |

1450 |

1240 |

1450 |

|

Coefficient de dilatation thermique |

10⁻⁶/K |

10 |

10 |

10 |

– |

10 |

|

Conductivité thermique |

Avec(m·K) |

3 |

3 |

3 |

3 |

3 |

|

Résistance aux chocs thermiques |

ΔT°C |

400 |

400 |

400 |

– |

400 |

|

Température d'utilisation maximale (Oxydant) |

°C |

1000 |

1000 |

1000 |

850 |

1000 |

|

Température d'utilisation maximale (Réducteur/Inerte) |

°C |

1000 |

1000 |

1000 |

850 |

1000 |

|

Résistivité volumique (20°C) |

Oh·cm |

10¹³ |

10¹² |

10¹² |

5×10¹³ |

10¹² |

|

Rigidité diélectrique |

kV/mm |

19 |

15 |

17 |

19 |

17 |

|

Constante diélectrique (1MHz) |

– |

28 |

30 |

30 |

27 |

30 |

|

Perte diélectrique (bronzageδ) |

– |

2×10⁻³ |

2×10⁻³ |

2×10⁻³ |

2×10⁻³ (1GHz) |

2×10⁻³ |

Comment sont fabriquées les céramiques de zircone?

- Acquisition de matières premières en zircone: La zircone est généralement extraite du zircon (ZrSiO₄) en utilisant des méthodes chimiques ou d'électrofusion.

- Méthode chimique: Le zircon réagit avec des substances alcalines telles que l'hydroxyde de sodium pour produire du zirconate de sodium., qui est ensuite soumis à une acidification, précipitation, et calcination pour obtenir de la zircone. Cette méthode donne une grande pureté mais est complexe et coûteuse.

Méthode d'électrofusion: Le zircon est fondu à haute température dans un four à arc électrique, et des agents réducteurs tels que le carbone sont ajoutés pour favoriser la réaction, provoquant la décomposition du zircon en zircone et dioxyde de silicium. Le dioxyde de silicium s'échappe sous forme gazeuse, enrichissant ainsi la zircone. Cette méthode est moins coûteuse et adaptée à une production à grande échelle. - Ajout de stabilisateur: Pour améliorer les performances de la zircone, des stabilisants tels que l'oxyde d'yttrium (ET₂OU₃) et oxyde de calcium (CaO) sont souvent ajoutés pour former de la zircone stabilisée ou partiellement stabilisée. Cela inhibe les transitions de phase lors du refroidissement à haute température, améliorer la ténacité et la stabilité du matériau.

- Pressage à sec: La poudre de zircone est mélangée uniformément avec une quantité appropriée de liant et de lubrifiant, puis placé dans un moule et comprimé à l'aide d'une presse pour compacter et façonner la poudre. Cette méthode est simple et adaptée aux produits de formes simples et de petites tailles, mais l'uniformité de la densité du corps vert est relativement mauvaise.

- Pressage isostatique: La poudre est placée dans un moule élastique puis dans un récipient haute pression. La pression est appliquée uniformément à travers un milieu liquide, provoquant la compression et la mise en forme de la poudre simultanément dans toutes les directions. Cette méthode donne des corps verts de densité uniforme et de haute résistance., et convient aux produits aux formes complexes et aux exigences de performances élevées.

- Coulée par glissement: La poudre de zircone est mélangée à de l'eau, dispersants, etc., former une bouillie, qui est ensuite coulé dans un moule en plâtre poreux. L’absorption d’eau du moule en plâtre élimine progressivement l’eau du coulis, et les particules de poudre se déposent sur la paroi du moule pour former la forme. Cette méthode convient à la fabrication de grandes, composants céramiques de forme complexe, mais la densité et la force du corps vert sont inférieures.

- Coulée à chaud: À une température plus élevée (60-100°C), la poudre de zircone est mélangée à des liants tels que la cire de paraffine pour former une suspension. La bouillie est injectée dans un moule métallique à l'aide d'air comprimé. Après maintien de la pression et refroidissement, le moule en cire est retiré, puis déciré pour obtenir le corps vert. Cette méthode produit des corps verts avec des dimensions précises et une efficacité de production élevée, mais il n'est pas adapté à la fabrication de gros composants.

- Coulée de bande: La poudre de zircone est soigneusement mélangée avec des liants organiques et des plastifiants pour former une suspension visqueuse. La boue est uniformément enduite sur une bande transporteuse à l'aide d'une racle pour contrôler l'épaisseur.. Après séchage, un corps vert en film mince est obtenu. Cette méthode convient à la préparation de matériaux en couches minces, mais nécessite un contrôle précis des paramètres du processus.

- Moulage par injection: La poudre de zircone est mélangée à un liant thermoplastique pour former un matériau de moulage par injection. Ce matériau est ensuite injecté dans un moule à l'aide d'une presse à injecter.. Cette méthode peut produire des produits aux formes complexes et de haute précision, et a une efficacité de production élevée, mais nécessite des matières premières et des équipements de haute qualité.

- Frittage sans pression: Le corps vert formé est placé dans un four à haute température et chauffé à une certaine température (généralement 1300-1500℃) dans un environnement atmosphérique, permettant aux particules du corps vert de se diffuser et de se lier les unes aux autres, parvenir à la densification. C'est la méthode de frittage la plus courante, simple à utiliser, mais nécessite des températures de frittage élevées et consomme beaucoup d'énergie.

Frittage par pressage à chaud: La pression et la température sont appliquées simultanément pendant le processus de frittage, permettant au corps vert de se densifier plus rapidement sous pression. Cette méthode peut abaisser la température de frittage et améliorer la densité et les performances du corps vert, mais l'équipement est complexe et le coût est élevé. - Pressage isostatique à chaud (HANCHE): Le corps vert est placé dans un récipient à haute pression, et haute température et haute pression sont appliquées simultanément, permettant au corps vert de se densifier sous une pression uniformément répartie. Cette méthode peut obtenir une haute densité, matériaux céramiques hautes performances, mais l'équipement est cher et le coût de production est élevé.

- Frittage par micro-ondes: Cette méthode utilise l'interaction entre le champ électromagnétique micro-ondes et le matériau céramique pour générer de la chaleur à l'intérieur du matériau., obtenir un frittage rapide. Cette méthode présente les avantages d'un chauffage uniforme, temps de frittage court, et faible consommation d'énergie, mais cela nécessite des exigences élevées en matière de matières premières et de paramètres de processus.

- Frittage au plasma étincelant (SPS): Un courant pulsé est utilisé pour générer un plasma de décharge entre les particules de poudre, produisant des températures et des pressions élevées, permettant au corps vert de se densifier rapidement. Cette méthode a une faible température de frittage et un temps de frittage court, et peut obtenir une haute densité, matériaux céramiques à grains fins, mais l'équipement est complexe et le coût est élevé.

- Après frittage, les céramiques de zircone peuvent nécessiter un traitement et un traitement supplémentaires, comme le broyage, polissage, coupe, et forage, pour répondre aux exigences de précision dimensionnelle et de qualité de surface du produit. En outre, pour certaines applications spéciales, des traitements de revêtement et de modification de surface peuvent être nécessaires pour améliorer les performances et la fonctionnalité de la céramique.

Applications de la céramique de zircone

- Restaurations dentaires: Utilisé pour fabriquer des couronnes dentaires, ponts, incrustations, et implants, offrant une excellente biocompatibilité, esthétique, haute résistance, et résistance à l'usure. Ils remplacent efficacement les dents abîmées, restaurer la fonction et l'apparence de la mastication.

- Articulations artificielles: Comme les articulations artificielles de la hanche et du genou, utilisant leur haute résistance, résistance à l'usure, et biocompatibilité pour réduire le rejet des implants par l’organisme et prolonger leur durée de vie.

- Instruments chirurgicaux: Certains instruments chirurgicaux utilisent un matériau en céramique de zircone, qui est résistant à la corrosion, antirouille, et conserve son tranchant pendant longtemps, ce qui les rend adaptés aux interventions chirurgicales nécessitant une hygiène et une précision élevées.

- Substrats de circuits intégrés: En tant que matériau isolant haute performance, il est utilisé dans l'emballage et les substrats des circuits intégrés, possédant une excellente isolation électrique, stabilité thermique, et résistance mécanique, ce qui contribue à améliorer les performances et la fiabilité des appareils électroniques.

- Matériaux isolants haute fréquence: Dans les équipements électroniques haute fréquence tels que les communications 5G et les radars, la céramique de zircone peut être utilisée comme couche isolante ou matériau diélectrique, répondre aux besoins de transmission de signaux haute fréquence et réduire la perte de signal et les interférences.

- Céramiques piézoélectriques: Utiliser son effet piézoélectrique, il est utilisé pour fabriquer des capteurs, transducteurs, et actionneurs, comme les capteurs de pression, capteurs d'accélération, et transducteurs à ultrasons. Il est largement utilisé dans des domaines tels que le contrôle d'automatisation, diagnostic médical, et surveillance environnementale.

- Composants du moteur: comme les aubes de turbine, revêtements de chambre de combustion, et buses, utiliser leur résistance aux hautes températures, haute résistance, et faible densité pour améliorer l'efficacité et la fiabilité du moteur, et réduire le poids des avions.

- Systèmes de protection thermique: utilisé comme tuiles thermiques et revêtements de protection thermique, ils protègent l'avion de l'érosion causée par le flux d'air à haute température lors d'un vol à grande vitesse ou d'une rentrée atmosphérique, assurer la sécurité de la structure de l'avion.

- Supports d'antenne satellite: utilisant leur poids léger, haute rigidité, et stabilité dimensionnelle, ils sont utilisés pour fabriquer des structures de support pour les antennes satellites, améliorer la précision de pointage et la stabilité des antennes.

- Composants du moteur: Tels que les chemises de cylindre de moteur, couronnes de piston, et bagues de siège de soupape, utiliser l'excellente isolation thermique et la résistance à l'usure de la céramique de zircone pour améliorer le rendement énergétique et les performances de puissance du moteur, et prolonger la durée de vie du moteur.

- Capteurs d'oxygène: Utilisé pour surveiller la teneur en oxygène dans les gaz d'échappement du moteur, permettant un contrôle précis du volume d'injection de carburant, améliorer l'efficacité de la combustion, et réduire les émissions d'échappement.

- Composants du système de freinage: Les disques et plaquettes de frein de certaines voitures haut de gamme utilisent des matériaux en céramique de zircone, qui ont une résistance à l'usure plus élevée, résistance à la chaleur, et performances de freinage, raccourcir la distance de freinage et améliorer la sécurité de conduite.

- Roulements en céramique: Doté d'une résistance à l'usure, résistance à la corrosion, résistance aux hautes températures, et autolubrification sans huile, ils conviennent aux vitesses élevées, systèmes de transmission mécaniques de haute précision dans des environnements difficiles, tels que des ventilateurs de refroidissement miniatures, instruments de précision, et broches de machines-outils.

- Vannes en céramique: Utilisé en chimie, pétrole, et industries métallurgiques pour contrôler le débit et la pression des fluides, ils offrent des avantages tels que la résistance à la corrosion, résistance à l'usure, et résistance aux hautes températures, et peut remplacer les vannes métalliques traditionnelles, prolonger la durée de vie.

- Outils de coupe: Tels que les outils de coupe en céramique, exercices, et fraises, ils possèdent une dureté élevée, haute résistance, et résistance à l'usure, ce qui les rend adaptés au traitement de matériaux de haute dureté tels que la fonte, acier trempé, et alliages haute température, améliorer l'efficacité et la précision du traitement.

- Piles à combustible à oxyde solide (SOFC): Utiliser leur conductivité ionique oxygène comme matériau électrolytique, Les SOFC permettent une conversion efficace du carburant et une production d'électricité, offrant des avantages tels qu'une efficacité de conversion énergétique élevée, grande adaptabilité du carburant, et une pollution environnementale minimale.

- Séparateurs de batteries à semi-conducteurs: Utilisé dans les batteries à semi-conducteurs comme canal de conduction ionique et couche d'isolation d'électrode, ces séparateurs possèdent une excellente stabilité chimique, résistance mécanique, et conductivité ionique, améliorer la densité énergétique et la sécurité de la batterie.

- Utilisation du solaire thermique: Comme matériau absorbant la chaleur ou isolant dans les capteurs solaires, sa résistance aux hautes températures, résistance à la corrosion, et une bonne conductivité thermique améliorent l'efficacité de l'utilisation de l'énergie solaire.

- Ferrules et manchons pour fibre optique: Utilisé dans les connecteurs de fibre optique, ces composants présentent une haute précision, faible perte d'insertion, et une grande stabilité, assurer une transmission efficace des signaux par fibre optique et des connexions fiables. Ce sont des composants critiques dans les réseaux de communication optiques.

- Isolateurs et circulateurs optiques: Utiliser les propriétés optiques et mécaniques de la céramique de zircone, ces composants sont fabriqués pour créer des isolateurs et des circulateurs optiques, permettant la transmission unidirectionnelle et le routage des signaux optiques, améliorant ainsi les performances et la stabilité des systèmes de communication optique.

Foire aux questions sur la céramique d'alumine

Quels sont les principaux avantages de la céramique zircone?

La céramique de zircone est appréciée pour sa haute résistance et sa ténacité à la rupture.

Par rapport à la plupart des céramiques techniques, il est plus résistant aux fissures et aux chocs.

Cela le rend adapté aux applications où la fiabilité mécanique est critique.

La céramique de zircone est-elle plus résistante que la céramique d'alumine?

La céramique de zircone a généralement une ténacité à la rupture plus élevée que la céramique d'alumine, ce qui signifie qu'il est moins fragile sous contrainte mécanique.

Alumine, cependant, peut offrir une meilleure résistance à l’usure et une meilleure stabilité thermique dans certaines conditions.

Le meilleur choix dépend de la manière dont le composant échoue en fonctionnement réel.

Qu'est-ce que la zircone stabilisée à l'yttria (YSZ)?

La zircone stabilisée à l'yttria est un oxyde de zirconium combiné à de l'oxyde d'yttrium..

Cette stabilisation améliore la stabilité de phase et la ténacité.

Il permet au matériau de conserver sa résistance sous charge et contrainte thermique..

La céramique de zircone peut-elle être utilisée dans des environnements à haute température?

La céramique de zircone fonctionne bien à des températures élevées et a une faible conductivité thermique.

Il est souvent utilisé là où une isolation thermique ou une stabilité thermique est requise.

Pour une exposition à long terme ou un cycle thermique rapide, les limites de fonctionnement doivent être soigneusement évaluées.

La céramique de zircone est-elle adaptée aux applications d'usure ou de glissement?

La céramique de zircone peut être utilisée dans les applications d'usure, surtout là où la résistance aux chocs est importante.

Pour des conditions d’usure purement abrasives, d'autres céramiques telles que l'alumine ou le carbure de silicium

peut offrir de meilleures performances en fonction de la conception du système.

Comment se comporte la céramique de zircone dans des environnements corrosifs?

La céramique de zircone présente une excellente résistance à la plupart des acides, alcalis, et produits chimiques industriels.

Cela le rend adapté au traitement chimique et aux environnements d’exploitation corrosifs

où les composants métalliques peuvent tomber en panne rapidement.

Les composants en céramique de zircone peuvent-ils être personnalisés?

Oui. Les composants en céramique de zircone peuvent être personnalisés en termes de qualité de matériau, taille, forme,

état de surface, et la tolérance.

La personnalisation permet de garantir un ajustement approprié et des performances stables dans des conditions de fonctionnement spécifiques.

Céramique JiFeng

Céramique JiFeng