Zirconia Ceramic Valves: Setting New Standards for Fluid Control in Demanding Applications

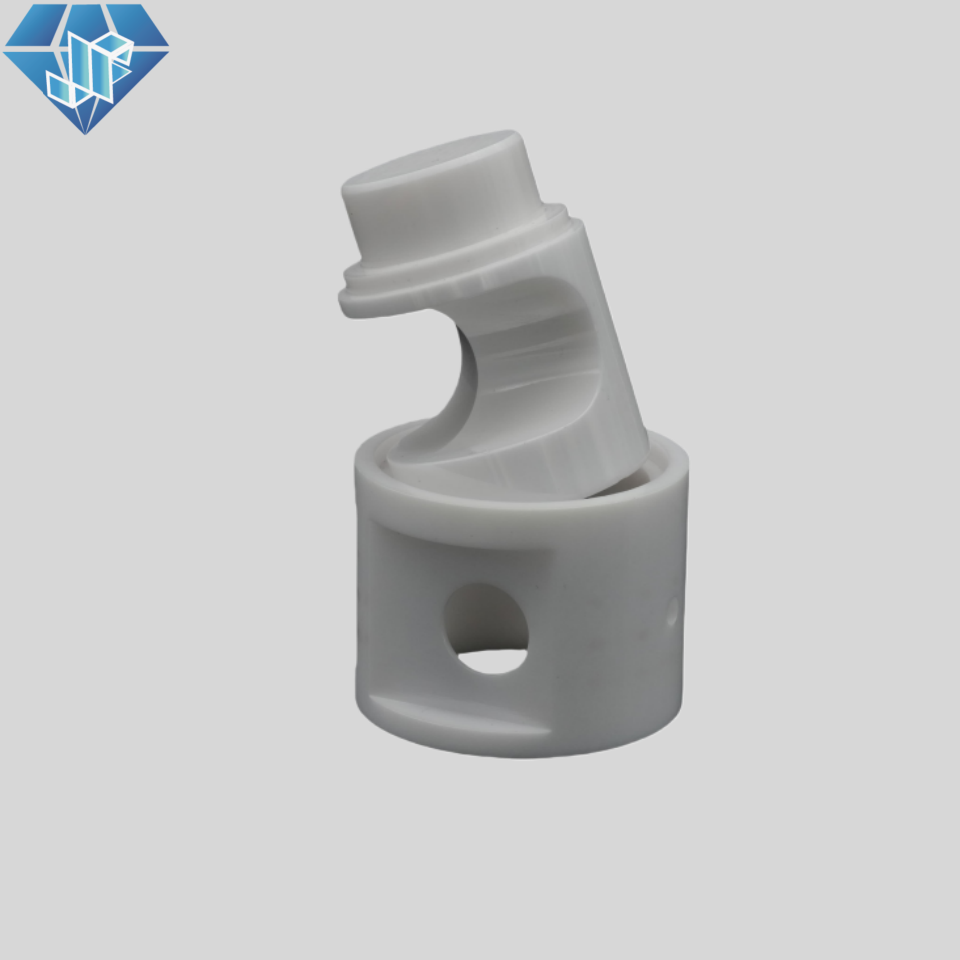

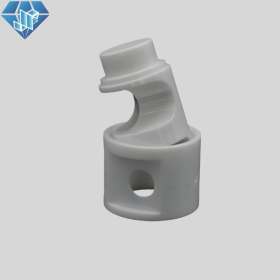

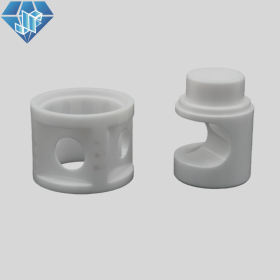

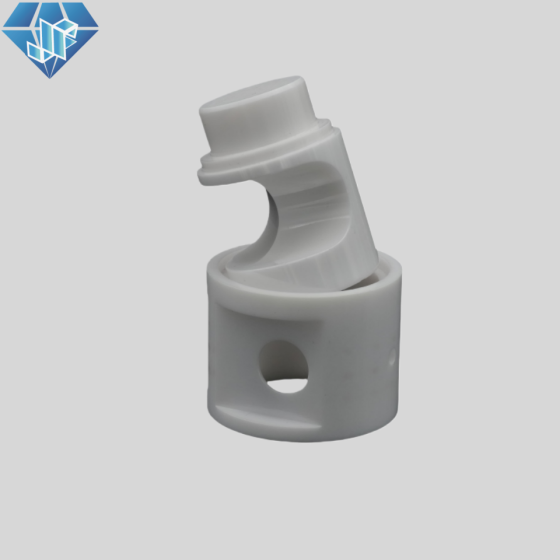

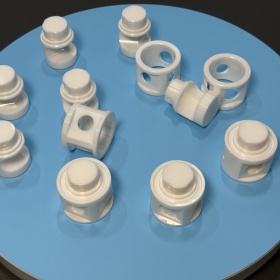

Zirconia Ceramic Valves rely on zirconia (ZrO₂) material. Specifically, they use Yttria-Stabilized Tetragonal Zirconia Polycrystal (YTZP) ceramic. Manufacturers produce this ceramic by adding stabilizers like yttria. After sintering, the material features a unique phase transformation toughening mechanism. This mechanism endows the valves with extremely high fracture toughness and thermal shock resistance. It also overcomes the brittleness of traditional ceramics. Key valve components—such as the plug, seat, and sealing surfaces—use high-purity, high-density zirconia ceramic. This ensures excellent and consistent overall performance. Notably, the white ceramic parts have a smooth, dense surface. Visually, this surface reflects their superior wear and corrosion resistance.

Technical Specifications of Zirconia Ceramic Valves

First, zirconia ceramic boasts exceptional corrosion resistance. It has high chemical inertness. It resists most strong acids, alkalis, and organic solvents—except hydrofluoric acid and hot concentrated sulfuric acid. Its service life far outlasts that of special metal valves, such as stainless steel or Hastelloy.

Additionally, it offers superior wear resistance and hardness. Its Vickers hardness exceeds HV1300. Only diamond and silicon carbide rank higher. When handling particle-containing media or slurries, it effectively resists erosion and wear. This maintains precise mating of sealing surfaces long-term. Consequently, it prevents internal leakage.

Moreover, the valves deliver excellent high-temperature resistance. They operate stably for long periods in oxidizing or inert atmospheres. The maximum operating temperature reaches 800°C without performance degradation. This makes them suitable for high-temperature flue gas, molten salt pipelines, and similar applications.

In terms of mechanical performance, they feature high strength and toughness. Thanks to phase transformation toughening, their flexural strength and fracture toughness lead among advanced ceramics. This allows them to withstand high pipeline pressure and mechanical shock.

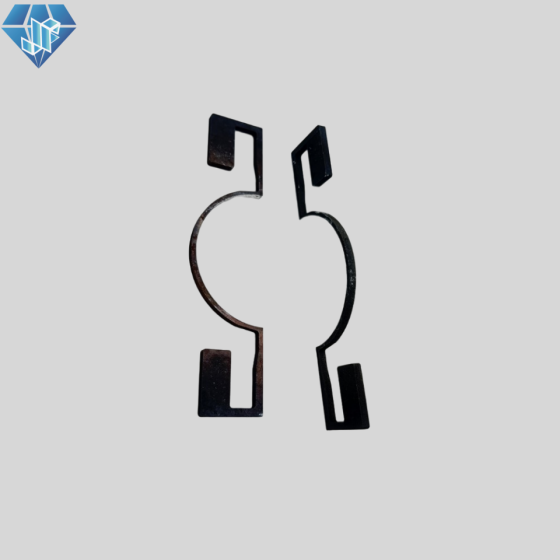

Beyond that, they ensure excellent sealing performance. Manufacturers can precision-machine ceramic parts to a mirror-like finish. This achieves metal-to-ceramic or ceramic-to-ceramic hard sealing. The leakage class reaches ANSI/FCI 70-2 Class VI or above, realizing near-zero leakage.

Finally, the material offers bio-inertness and cleanliness. It is non-toxic and non-contaminating. Its surface is smooth and non-adherent. It complies with FDA requirements. This makes it ideal for food, pharmaceutical, and bioengineering applications.

Applications

In the chemical and petroleum industries, these valves convey and regulate aggressive media. Examples include strong acids, alkalis, salt solutions, solvents, and harsh oilfield fluids. They effectively solve corrosion and wear challenges in these sectors.

For the food and pharmaceutical industries, they serve as sanitary valves in CIP/SIP systems. They ensure media purity. Meanwhile, they prevent bacterial growth and cross-contamination.

In power and environmental protection fields, they find use in desulfurization, denitrification, fly ash handling, and coal-water slurry transport systems. They resist wear and corrosion in these harsh environments.

Within the semiconductor and electronics industries, they transport high-purity chemicals—such as acids, alkalis, and slurries. This avoids metallic ion contamination of sensitive electronic components.

Additionally, they suit the paper, metallurgy, and textile industries. They handle various corrosive and abrasive slurries and chemicals in these sectors.

JiFeng Ceramics

JiFeng Ceramics