Advanced Ceramic Materials – Properties, Types and Industrial Applications

Advanced ceramic materials, also known as technical or engineering ceramics, are high-performance materials engineered for demanding industrial environments. Compared with traditional ceramics, metals, and polymers, advanced ceramics offer superior mechanical strength, thermische Stabilität, chemical resistance, and electrical performance.

Due to these outstanding properties, advanced ceramic materials are widely used in industries such as semiconductor manufacturing, aerospace, medical devices, Elektronik, energy, and industrial wear applications. This page provides a comprehensive overview of ceramic material classifications, properties, manufacturing processes, and selection guidelines to help engineers and procurement professionals choose the right ceramic solution.

What Are Advanced Ceramic Materials?

Advanced ceramic materials are inorganic, non-metallic materials that are specifically designed and processed to achieve precise mechanical, thermal, electrical, or chemical performance. Unlike traditional ceramics used in construction or household products, engineering ceramics are manufactured under strict quality control to meet high technical standards.

Key advantages of advanced ceramic materials include:

Exceptional hardness and wear resistance

High temperature stability and thermal shock resistance

Excellent corrosion and chemical resistance

Electrical insulation or functional conductivity

Long service life in extreme environments

These characteristics make advanced ceramics an ideal choice where conventional materials fail.

Classification of Ceramic Materials

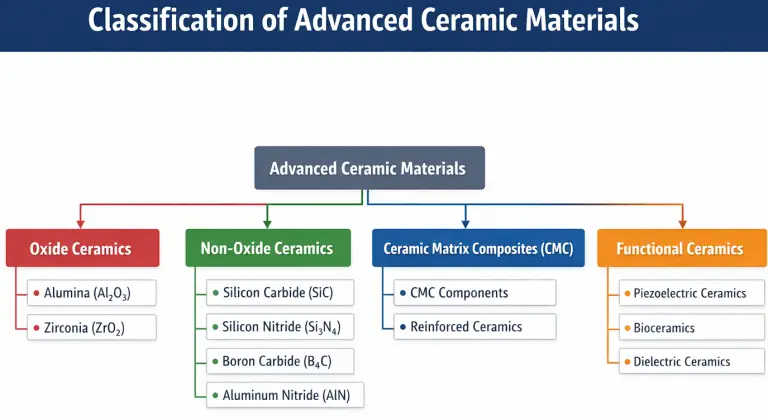

Advanced ceramic materials can be broadly classified into oxide ceramics, non-oxide ceramics, ceramic matrix composites, and functional ceramics.

Oxide Ceramics

Oxide ceramics are the most widely used engineering ceramics due to their good stability, cost-effectiveness, and balanced performance.

Aluminum oxide ceramics are one of the most widely used advanced ceramic materials. They possess high hardness, excellent electrical insulation, good wear resistance, and high-temperature stability. Aluminum oxide ceramics are widely used in electrical insulators, wear-resistant components, seals, and structural parts.

Zirconium oxide ceramics are known for their excellent fracture toughness and strength, surpassing other ceramic materials. They exhibit outstanding resistance to crack propagation and are commonly used in medical devices, precision mechanical components, and high-load applications.

Non-Oxide Ceramics

Non-oxide ceramics are typically selected for extreme conditions requiring superior thermal or mechanical performance.

Silicon carbide ceramic offers outstanding hardness, high thermal conductivity, and excellent chemical resistance. It is ideal for high-temperature applications, wear components, and semiconductor processing equipment.

Silicon nitride ceramic combines high strength, low density, and excellent thermal shock resistance. It is commonly used in bearings, automotive components, and high-speed mechanical systems.

Aluminum nitride ceramic features high thermal conductivity and excellent electrical insulation, making it suitable for electronic substrates and heat dissipation components.

Boron carbide is an ultra-hard ceramic material with low density, often used in armor systems, abrasive applications, and wear-resistant components.

eramic Matrix Composites (CMC)

Ceramic matrix composites are reinforced ceramic materials designed to improve toughness and damage resistance. These materials are used in aerospace, energy, and high-temperature structural applications where both strength and reliability are critical.

Functional Ceramics

Functional ceramics are engineered to provide specific electrical, magnetic, or biological functions, such as piezoelectric ceramics, bio-ceramics, and dielectric materials used in sensors, medical implants, and electronic devices.

Key Properties of Engineering Ceramic Materials

Advanced ceramic materials are selected based on a combination of critical properties:

Mechanische Eigenschaften: high hardness, compressive strength, and wear resistance

Thermal Properties: high melting point, thermische Stabilität, and thermal shock resistance

Electrical Properties: insulation, dielectric performance, or controlled conductivity

Chemical Resistance: resistance to corrosion, oxidation, and aggressive chemicals

These properties allow ceramics to outperform metals and polymers in harsh operating conditions.

Ceramic Manufacturing and Processing Technologies

The performance of advanced ceramic materials strongly depends on precise manufacturing processes. Typical ceramic production includes:

Powder preparation and formulation

Forming processes such as dry pressing, isostatic pressing, or injection molding

High-temperature sintering to achieve full density

Precision machining and finishing for tight tolerances

Advanced manufacturing ensures consistent material properties and reliable performance for critical applications.

Industrial Applications of Ceramic Materials

Advanced ceramic materials are widely applied across multiple industries:

Semiconductor & Electronics: insulating components, wafer handling parts, and thermal management solutions

Aerospace & Aviation: high-temperature structural parts and wear-resistant components

Medical Devices: biocompatible ceramic components and precision mechanical parts

Industrial Wear Parts: seals, valves, nozzles, and abrasion-resistant components

Energy & Chemical Industry: corrosion-resistant and high-temperature ceramic parts

Their versatility makes ceramics an essential material choice for modern industrial systems.

Ceramic Material Selection Guide

Selecting the right ceramic material depends on application requirements:

High temperature and thermal shock resistance → Silicon Carbide or Silicon Nitride

High toughness and mechanical strength → Zirconia

Cost-effective and versatile performance → Alumina

High thermal conductivity for electronics → Aluminum Nitride

Proper material selection improves component reliability, performance, and service life.

Why Choose Jifeng Advanced Ceramic Materials

Jifeng specializes in the development and manufacturing of high-quality advanced ceramic materials and precision ceramic components. With comprehensive material expertise, advanced processing capabilities, and strict quality control, we provide customized ceramic solutions tailored to specific industrial requirements.

Whether you need standard ceramic materials or custom-engineered ceramic components, our team supports you from material selection to final production.

Contact Us for Ceramic Material Solutions

If you require technical support or customized ceramic materials for your application, please contact us to discuss your project requirements.

JiFeng-Keramik

JiFeng-Keramik